-

Notifications

You must be signed in to change notification settings - Fork 11

Virtual Wheel of Items with a Physical Knob using Servos Motors

Immersive Experience, Week 1: Federico, Fahmida, Chaeri

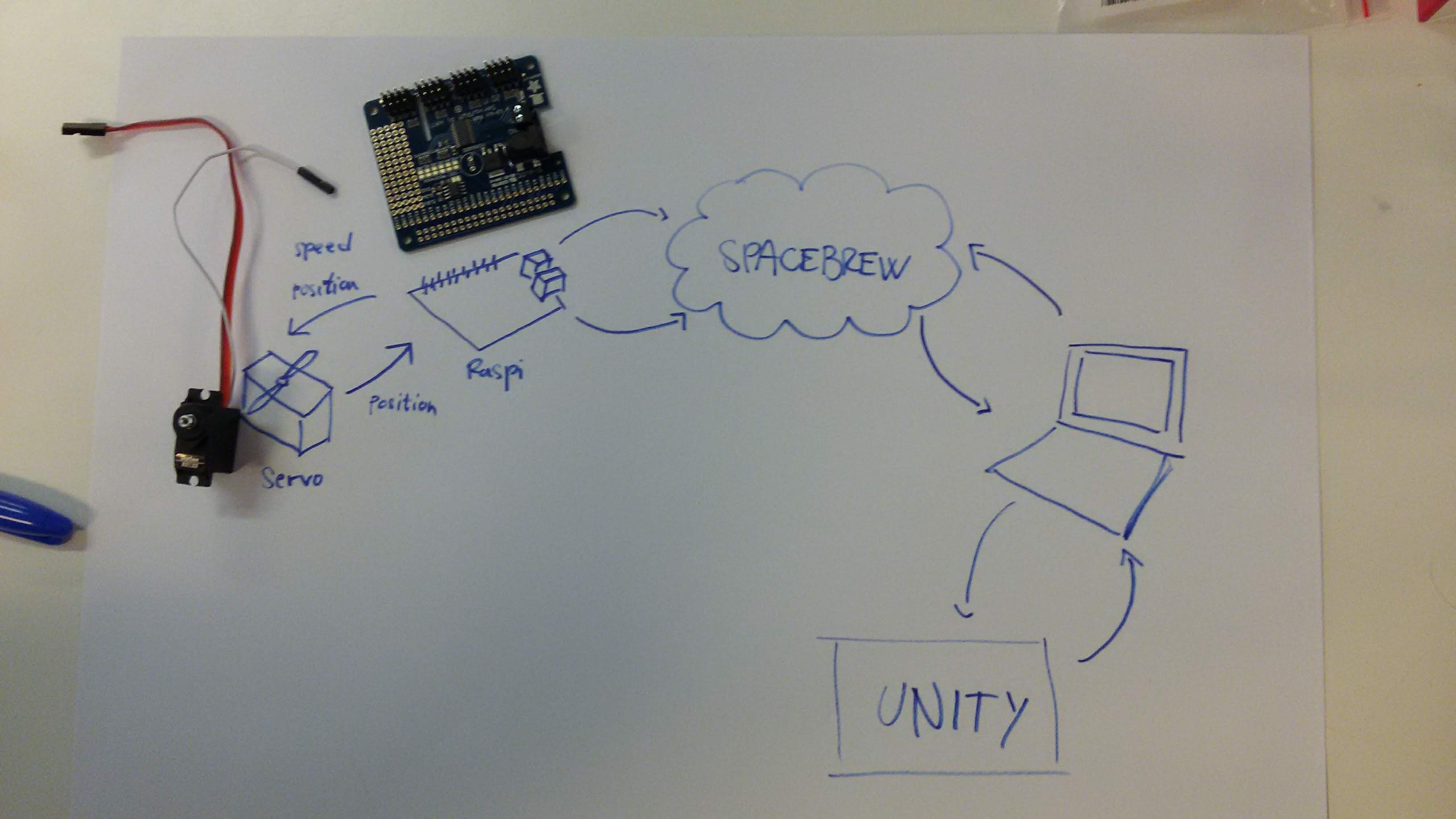

This tutorial will take you through connecting two servo motors to a Servo Hat that sends information via Spacebrew to Unity.

What we set out to do was to see if we could control two servo motors using the Servo Hat (attached to a Raspberry Pi) to send information to Unity via Spacebrew, so that a physical object could control a virtual output.

Once we were able to get the servo motor readings on the Raspberry Pi, we were able to control one servo motor digitally by moving the other servo motor manually. That was super cool. We were then inspired to think about how both servo motors could play a role for a virtual experience. What we decided to do, and what this tutorial will walk through, is to use one servo motor (which will function as a physical knob) to influence the movement of the second servo motor (which will function as an indicator) to dial through a series of virtual items (scrumptious meals).

- 2 servo motors

- Raspberry Pi 3 Model B+

- 5v 2A Power Plug

- Adafruit 16-Channel PWM / Servo HAT for Raspberry Pi

- MCP3008 - Analog to Digital Converter for Raspberry Pi (more info about this here: https://learn.adafruit.com/raspberry-pi-analog-to-digital-converters/overview)

- We soldered few of these female headers to the Servo Hat for easier wiring

- Python

- Unity

- Spacebrew

Here's what ours looked like.

This helped us understand the ways in which pieces of information would need to communicate to each other. It also helped us chunk the project so that we could work on one small piece at a time.

We soldered female headers to the Servo Hat so that it could be mounted on top of the Raspberry Pi, male headers to plug the servos.

Lastly we soldered more female headers on the hat to access the rest of the GPIO: this is necessary to work with the ADC later.

# Simple demo of of the PCA9685 PWM servo/LED controller library.

# Move 2 servos

from __future__ import division

import time

# Import the PCA9685 module.

import Adafruit_PCA9685

# Uncomment to enable debug output.

#import logging

#logging.basicConfig(level=logging.DEBUG)

# Initialise the PCA9685 using the default address (0x40).

pwm = Adafruit_PCA9685.PCA9685()

# Alternatively specify a different address and/or bus:

#pwm = Adafruit_PCA9685.PCA9685(address=0x41, busnum=2)

# Configure min and max servo pulse lengths

servo_min = 150 # Min pulse length out of 4096

servo_max = 600 # Max pulse length out of 4096

# Helper function to make setting a servo pulse width simpler.

def set_servo_pulse(channel, pulse):

pulse_length = 1000000 # 1,000,000 us per second

pulse_length //= 60 # 60 Hz

print('{0}us per period'.format(pulse_length))

pulse_length //= 4096 # 12 bits of resolution

print('{0}us per bit'.format(pulse_length))

pulse *= 1000

pulse //= pulse_length

pwm.set_pwm(channel, 0, pulse)

# Set frequency to 60hz, good for servos.

pwm.set_pwm_freq(60)

print('Moving servo on channel 0 and 4, press Ctrl-C to quit...')

while True:

# Move servo on channel O between extremes.

pwm.set_pwm(0, 0, servo_min)

pwm.set_pwm(4, 0, servo_min)

time.sleep(1)

pwm.set_pwm(0, 0, servo_max)

pwm.set_pwm(4, 0, servo_max)

time.sleep(1)

Here is how we connected the MCP3008 to our circuit.

What our readings looked like:

# RaspberryPi code to use a servo as input and broadcast/receive data via SpaceBrew

# By moving one servo, the other will move to the same position.

# Be sure to connect the Publisher and Subscriber in SpaceBrew

from __future__ import division

import sys

import time

import subprocess

from pySpacebrew.spacebrew import Spacebrew

# Import the PCA9685 module.

import Adafruit_PCA9685

import RPi.GPIO as GPIO

GPIO.setmode(GPIO.BCM)

DEBUG = 0

# read SPI data from MCP3008 chip, 8 possible adc's (0 thru 7)

def readadc(adcnum, clockpin, mosipin, misopin, cspin):

if ((adcnum > 7) or (adcnum < 0)):

return -1

GPIO.output(cspin, True)

GPIO.output(clockpin, False) # start clock low

GPIO.output(cspin, False) # bring CS low

commandout = adcnum

commandout |= 0x18 # start bit + single-ended bit

commandout <<= 3 # we only need to send 5 bits here

for i in range(5):

if (commandout & 0x80):

GPIO.output(mosipin, True)

else:

GPIO.output(mosipin, False)

commandout <<= 1

GPIO.output(clockpin, True)

GPIO.output(clockpin, False)

adcout = 0

# read in one empty bit, one null bit and 10 ADC bits

for i in range(12):

GPIO.output(clockpin, True)

GPIO.output(clockpin, False)

adcout <<= 1

if (GPIO.input(misopin)):

adcout |= 0x1

GPIO.output(cspin, True)

adcout >>= 1 # first bit is 'null' so drop it

return adcout

# change these as desired - they're the pins connected from the

# SPI port on the ADC to the Cobbler

SPICLK = 18

SPIMISO = 23

SPIMOSI = 24

SPICS = 25

# set up the SPI interface pins

GPIO.setup(SPIMOSI, GPIO.OUT)

GPIO.setup(SPIMISO, GPIO.IN)

GPIO.setup(SPICLK, GPIO.OUT)

GPIO.setup(SPICS, GPIO.OUT)

# 10k trim pot connected to adc #0

potentiometer_adc = 0;

last_read = 0 # this keeps track of the last potentiometer value

tolerance = 5 # to keep from being jittery we'll only change

# volume when the pot has moved more than 5 'counts'

# Initialise the PCA9685 using the default address (0x40).

pwm = Adafruit_PCA9685.PCA9685()

# Alternatively specify a different address and/or bus:

#pwm = Adafruit_PCA9685.PCA9685(address=0x41, busnum=2)

# Configure min and max servo pulse lengths

servo_min = 118 # Min pulse length out of 4096

servo_max = 600 # Max pulse length out of 4096

#set servo potentiometers minimum and maximum reading values

pot_min = 37

pot_max = 772

#set servo potentiometers minimum and maximum values to be published

degree_min = 0

degree_max = 180

# Helper function to make setting a servo pulse width simpler.

def set_servo_pulse(channel, pulse):

pulse_length = 1000000 # 1,000,000 us per second

pulse_length //= 60 # 60 Hz

print('{0}us per period'.format(pulse_length))

pulse_length //= 4096 # 12 bits of resolution

print('{0}us per bit'.format(pulse_length))

pulse *= 1000

pulse //= pulse_length

pwm.set_pwm(channel, 0, pulse)

# Set frequency to 60hz, good for servos.

pwm.set_pwm_freq(60)

def translate(value, leftMin, leftMax, rightMin, rightMax):

# Figure out how 'wide' each range is

leftSpan = leftMax - leftMin

rightSpan = rightMax - rightMin

# Convert the left range into a 0-1 range (float)

valueScaled = float(value - leftMin) / float(leftSpan)

# Convert the 0-1 range into a value in the right range.

return rightMin + (valueScaled * rightSpan)

# Setting up Spacebrew

brew = Spacebrew("Servo_Carousel_RPI", description="Move a servo and let the other one follow", server="sandbox.spacebrew.cc", port=9000)

# publish servo 1 position - range

brew.addPublisher("position", "range");

# listen servo 2 position - range

brew.addSubscriber("rotation", "range")

#Spacebrew Server Status

connected = False

#CHECK_FREQ = 2 # check mail every 2 seconds

def handleRotation(value):

if DEBUG:

print("Received: "+str(value))

servo2pos = translate(potValue, 0, 180, servo_min, servo_max)

servo2pos = round(servo2pos)

servo2pos = int(servo2pos)

pwm.set_pwm(4, 0, servo2pos)

brew.subscribe("rotation", handleRotation)

try:

brew.start()

print('Servo carousel is taking off...CTRL+C to exit')

while True:

if (connected == True):

# we'll assume that the pot didn't move

trim_pot_changed = False

# read the analog pin

trim_pot = readadc(potentiometer_adc, SPICLK, SPIMOSI, SPIMISO, SPICS)

# how much has it changed since the last read?

pot_adjust = abs(trim_pot - last_read)

#print values to debug

if DEBUG:

print "trim_pot:", trim_pot

print "pot_adjust:", pot_adjust

print "last_read", last_read

#adjust tolerance

if ( pot_adjust > tolerance ):

trim_pot_changed = True

#print values for debug

if DEBUG:

print "trim_pot_changed", trim_pot_changed

#if the servo has been moved

if ( trim_pot_changed ):

#convert the readings from the servo into a value between 0 and 180 degrees

potValue = translate(trim_pot, pot_min, pot_max, degree_min, degree_max )

potValue = round(potValue) # round out decimal value

potValue = int(potValue) # cast as integer

#publish to spacebrew

brew.publish("position", potValue)

# servo2pos = translate(potValue, 0, 180, servo_min, servo_max)

# servo2pos = round(servo2pos)

# servo2pos = int(servo2pos)

# pwm.set_pwm(4, 0, servo2pos)

if DEBUG:

print "potValue", potValue, "degrees"

#print "tri_pot_changed", potValue

# save the potentiometer reading for the next loop

last_read = trim_pot

connected = True

# hang out and do nothing for a half second

time.sleep(0.2)

finally:

GPIO.cleanup()

brew.stop()Decide how many elements you’d like to have in your scene, and use Google Poly to find the 3d models that you’d like to use. which elements you’d like to have in your scene. Then rotate each item so that they are spatially laid out in the order that you’d like.

Add an event listener in the setup function of SpacebrewEvents.cs script:

sbClient.addEventListener (this.gameObject, "foodPointer"); Make individual scripts for each item that will animate. Then you’ll have to update the subscriber events with the controls for the specific script. Inside the function OnSpacebrewEvent get the data from Spacebrew and parse the data into a float. The float will then be sent to a custom function into each object’s specific script. We use the same function for all the objects.

if (_msg.name == "foodPointer") {

//print ("Message Received: "+_msg.value);

pointerRotation = float.Parse(_msg.value, System.Globalization.CultureInfo.InvariantCulture.NumberFormat);

// Access the script of the Hotdogs on the left

// First point at the Object

GameObject hotdog_0 = GameObject.Find("BaseBoARd/YourObjectsGoHere/hotdog_0");

// then point at the script

scaleHotdog_0 scaleHD_0 = hotdog_0.GetComponent <scaleHotdog_0> ();

// Lastly pass the float to the controlScale function of the script

scaleHD_0.controlScale(pointerRotation);

// Access the script of the Hotdogs on the right

GameObject hotdog_180 = GameObject.Find("BaseBoARd/YourObjectsGoHere/hotdog_180");

ScaleHotdog_180 scaleHD_180 = hotdog_180.GetComponent <ScaleHotdog_180> ();

scaleHD_180.controlScale(pointerRotation);

// Access the script of the burrito

GameObject burrito = GameObject.Find("BaseBoARd/YourObjectsGoHere/burrito");

BurritoScale scaleBurrito = burrito.GetComponent <BurritoScale> ();

scaleBurrito.controlScale(pointerRotation);

GameObject taco = GameObject.Find("BaseBoARd/YourObjectsGoHere/taco");

TacoScale scaleTaco = taco.GetComponent <TacoScale> ();

scaleTaco.controlScale(pointerRotation);

GameObject burger = GameObject.Find("BaseBoARd/YourObjectsGoHere/burger");

BurgerScale scaleBurger = burger.GetComponent <BurgerScale> ();

scaleBurger.controlScale(pointerRotation);

GameObject sandwich = GameObject.Find("BaseBoARd/YourObjectsGoHere/sandwich");

SandwichScale scaleSandwich = sandwich.GetComponent <SandwichScale> ();

scaleSandwich.controlScale(pointerRotation);

}Each 3D model has a script to change the scale. That's the script with the function we will call from the OnSpacebrewEvent.

All the model have the same script with different ranges in the Map functions:

using System.Collections;

using System.Collections.Generic;

using UnityEngine;

public class SandwichScale : MonoBehaviour {

float maxScale = 80f;

float minScale = 0f;

float currScale;

// Use this for initialization

void Start () {

}

// Update is called once per frame

void Update () {

}

static float Map (float from1, float to1, float from2, float to2, float value) {

return (value - from1) / (to1 - from1) * (to2 - from2) + from2;

}

public void controlScale(float _val){

if (_val > 130f && _val < 140f ) {

transform.localScale = new Vector3 (maxScale, maxScale, maxScale);

} else if (_val > 120f && _val <= 130f) {

currScale = Map(120f, 130f, minScale, maxScale, _val);

print("Current scale is: "+currScale);

transform.localScale = new Vector3 (currScale, currScale, currScale);

} else if (_val > 140f && _val <= 150f) {

currScale = Map(140f, 150f, maxScale, minScale, _val);

print("Current scale is: "+currScale);

transform.localScale = new Vector3 (currScale, currScale, currScale);

} else if (_val < 120f || _val > 150f ) {

transform.localScale = new Vector3 (minScale, minScale, minScale);

}

}

}The first and last 3d Objects have a slightly different code.

using System.Collections;

using System.Collections.Generic;

using UnityEngine;

public class scaleHotdog_0 : MonoBehaviour {

float maxScale = 70f;

float minScale = 0f;

float currScale;

public Renderer rend;

// Use this for initialization

void Start () {

rend = GetComponent<Renderer>();

}

// Update is called once per frame

void Update () {

}

static float Map (float from1, float to1, float from2, float to2, float value) {

return (value - from1) / (to1 - from1) * (to2 - from2) + from2;

}

public void controlScale(float _val){

if (_val < 20f) {

transform.localScale = new Vector3 (maxScale, maxScale, maxScale);

} else if (_val >= 20f && _val <= 30f) {

currScale = Map(20f, 30f, maxScale, minScale, _val);

print("Current scale is: "+currScale);

transform.localScale = new Vector3 (currScale, currScale, currScale);

} else if (_val > 30) {

transform.localScale = new Vector3 (0f, 0f, 0f);

}

}

}We fit all of our electronics inside a small box made of MDF.

Lining up our food items and the physical indicator with the fiducial image.

What we came up with!